APROMON

PiControl Solutions APROMON advanced process monitoring software can quickly and easily monitor the PID and advanced process control (APC) quality of all controllers in any factory or manufacturing plant.

APROMON

APROMON: Continuous Online Process Control Performance Monitoring and Diagnostics Software

Manufacturing plants can have anywhere from 10 to as many as 5 000 PID and/or advanced process control (APC) loops, depending on the size and type of the process. As time goes by, process dynamics, process and equipment conditions, goals and objectives of the plant can change significantly. If PID tuning parameters are not optimal, control action can be slow or unstable and oscillatory. Bad PID control action can reduce product quality, make products sub-prime, off-spec, prevent production rate maximization, increase air pollution emissions, cause unplanned plant upsets and shutdowns, wear-and-tear on equipment, reduce life of control valves and moving machinery and distract the operators and engineers on focusing on other important tasks in the factory.

Therefore, PID control loops and advanced process control (APC) systems need to be monitored continuously. Nowadays, still less than 15 % of plants use adequate process control monitoring solutions and technology. A big opportunity to run plants better, more efficiently and increase profits is missed. Automatic online monitoring software is an essential tool to monitor the performance and control quality of all PID and advanced process control (APC) loops.

PiControl Solutions APROMON advanced process monitoring software can quickly and easily monitor the PID and advanced process control (APC) quality of all controllers in any factory or manufacturing plant.

See below overview of APROMON functionalities:

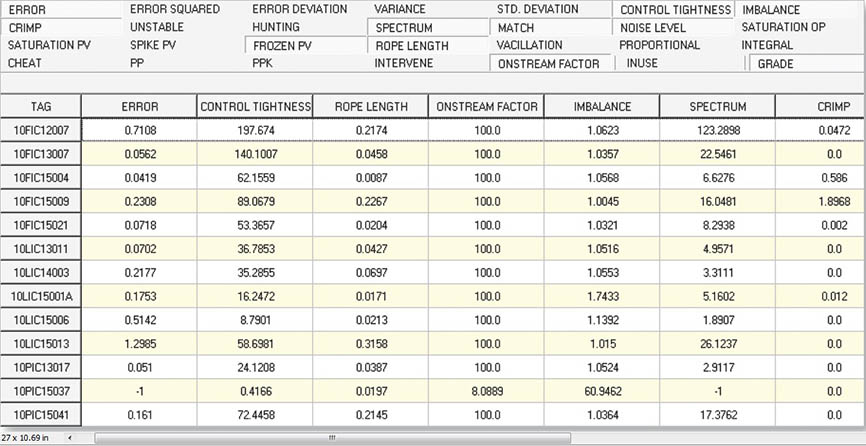

- examines PID, multivariable PID, cascade and override PID control quality based on over 25 statistical and process control quality criteria.

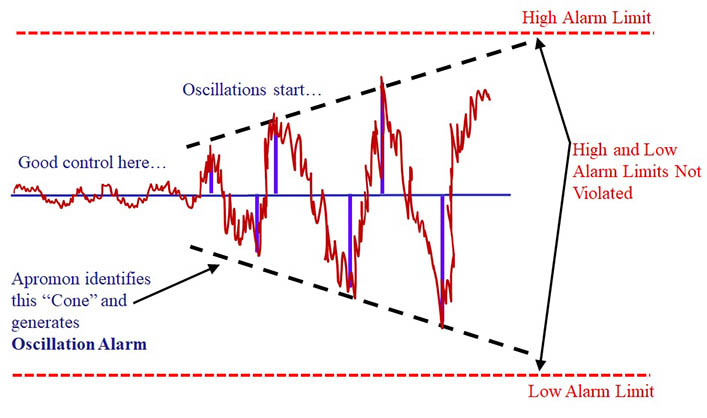

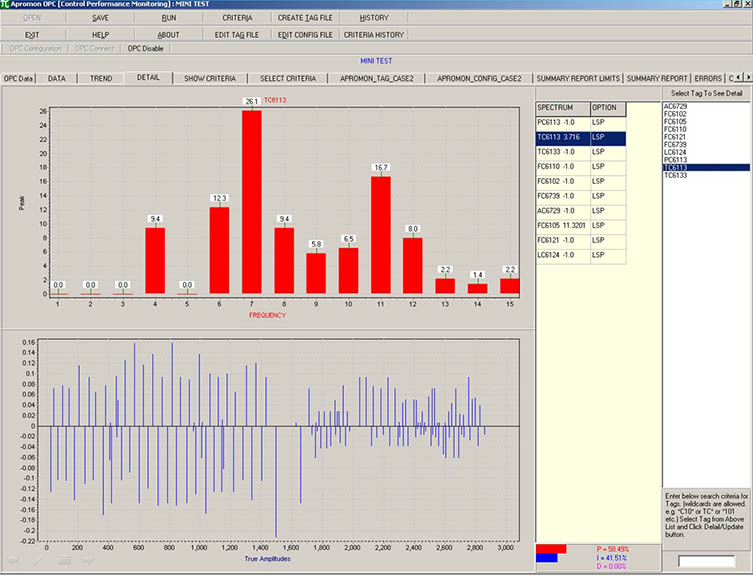

- has true amplitude detection (TAD) algorithm, the major breakthrough in its ability to reliably detect oscillations, instability, and hunting without getting fooled by the noise and squiggles that are present in process data.

- generates a report, sorting all PID control loops in the order of control quality.

- displays an online grade report and diagnostic messages for all PIDs indicating their health and control quality.

- send online email/text alerts when the control quality of PID control loops deteriorate.

- detects control loops which are not controlling well, oscillatory or sluggish or even which control loops are interactive.

- detects which control valves do not work well, move excessively, oversized/undersized or have hysteresis and stiction, or even which instruments have signal problems such as frozen, spikey, or noisy value or a range issue.

- alerts if PID control loops are often in manual, auto or in cascade mode or even if operator makes too many mode changes.

- it that has a special algorithm to decompose the total control valve movement into individual proportional, integral and derivative contributions.

- it comes in online (OPC) or in offline (Excel) mode. With OPC, APROMON runs automatically and connects as OPC client to any DCS or PLC using OPC server. With Excel, APROMON can read Excel/CSV file data generated by any plant historian and perform calculations offline.

Inquire About APROMON

Talk With The Expert

Contact Email

Info@LeKaControl.com

Call Us

+385 95 8210 600

Office

Meštrovićev trg 8

10 020 Zagreb, Croatia