PITOPS

PiControl Solutions software product PITOPS is a multivariable closed-loop system identification, PID control loop tuning and advanced process control (APC) design and optimization.

PITOPS

PITOPS: Multivariable Closed-Loop System Identification, PID Tuning and Advanced Process Control (APC) Optimizer

Nowadays, many experienced process control and chemical engineers and DCS / PLC technicians have retired. Many new, young and inexperienced process control and chemical engineers, DCS / PLC technicians and control room operators have entered any manufacturing and chemical plants. Lack of modern, effective and practical process control tools has resulted in many missed opportunities in maximizing plant performance and plant profits. Avoidable mistakes and plant shutdowns due to poor process control impacts plant performance continuously.

For successful and effective primary and/or advanced process control (APC) in any industry, two areas are critical and essential: 1st is system identification and a 2nd one is PID and/or advanced process control (APC) design and optimization.

Accurate system identification is a prerequisite for good PID and/or advanced process control (APC) design. Unfortunately, still most of system identification methods are too complex and not so efficient for the use in the control room of any chemical plants. Due to the challenges and limitations on the practical success of system identification, precise and adequate dynamic models are rarely available.

PID control loop tuning and advanced process control (APC) are increasingly important today. PID control loop tuning helps chemical plants to run better, more smoothly. Advanced process control (APC) increases production rate and plant profits.

Many PID control loops may work “satisfactorily”, but with appropriate PID tuning, the performance of these PID and advanced process control (APC) loops could be much better if there is no lack of awareness of the potential and the resulting benefits. This can result in 2 to 4 % profits, sometimes as high as 10 %. Unfortunately, only fewer than 10 % of all plants worldwide are precisely tuned using PID control loop tuning and advanced process control (APC) optimization software. Often the age-old trial-and-error method of tuning or determination of other advanced process control (APC) parameters is used with little chance of good control quality performance, often followed with oscillations or sluggish control.

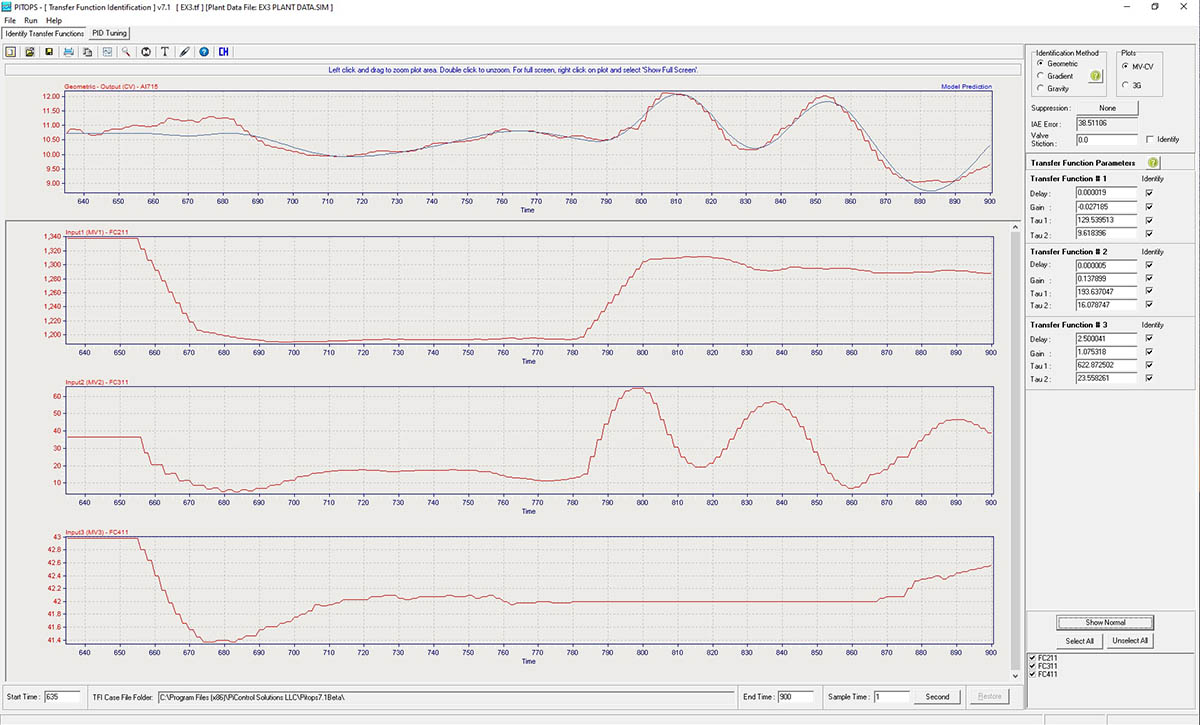

PiControl Solutions software product PITOPS is a multivariable closed-loop system identification, PID control loop tuning and advanced process control (APC) design and optimization. Here are the several of many other functionalities that distinguish and separate it from the world-wide competition:

- can identify single-input single-output (SISO), multiple-input single-output (MISO) and multiple-input multiple-output (MIMO) open-loop transfer functions with completely closed-loop data with controllers even in cascade mode.

- works entirely in the time domain (no need for Laplace and Z-domain knowledge).

- works with highly oscillatory data in closed-loop auto/cascade mode.

- works with both closed-loop and open-loop data and can work with data with the PID control loops in not only auto modes but even in cascade modes without the need for any intrusive step-tests that can potentially cause process upsets.

- can process any number of cascade and slave loops in a chain simultaneously.

- identifies process models even if data has large noise and unmeasured disturbances.

- identifies control valve stiction which can be included during PID control loop tuning.

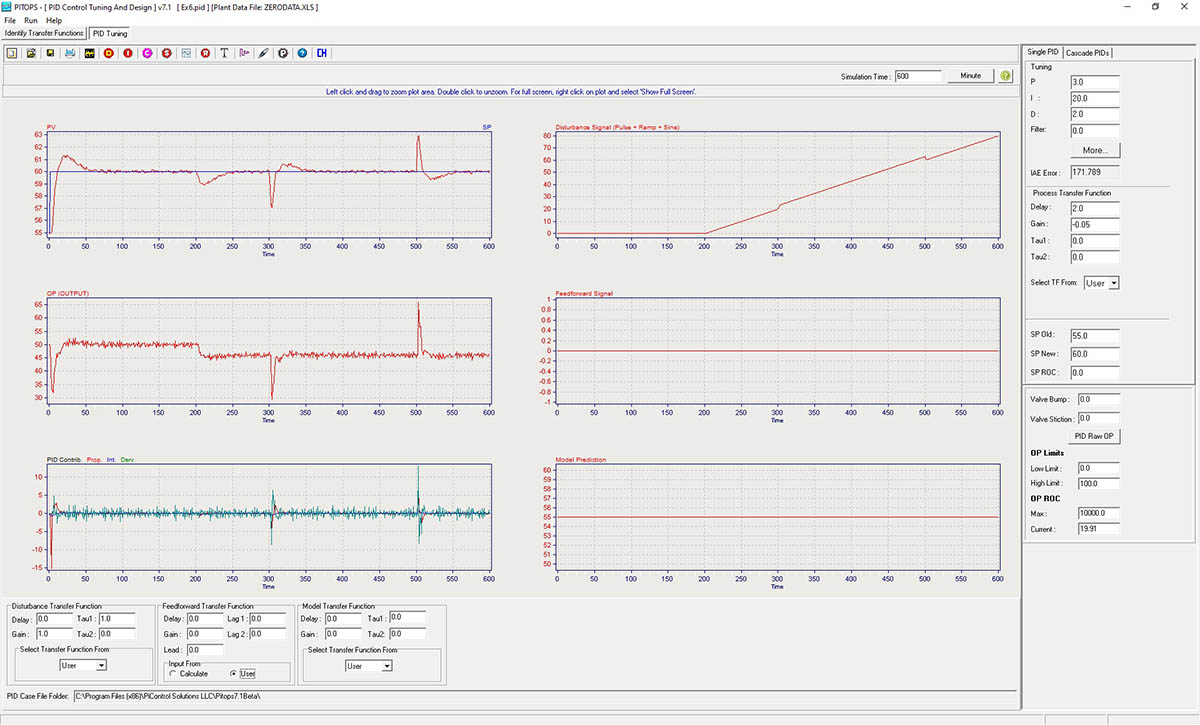

- it works and optimizes any PID control loop of any DCS / PLC vendor.

- allows custom configuration of any PID control loop with the same conditions as in any real DCS/PLC followed by PID control loop optimization.

- optimizes PID control loop parameters based on SP change, disturbances and noise as exactly encountered in any industry process.

- optimizer allows imposing a rate of change (R0C) on the control valve movement or the slave PID controller’s setpoint movement to avoid jerking and disturbing the downstream unit, equipment, and process.

- works with super-fast dynamics like compressors and turbines in milliseconds or with super-slow PID loops like online analyzer scanning in minutes and/or hours.

- allows changing process model & PID control loop tuning parameters to simulate what-if case and PID robustness analysis.

- can be used on nonlinear processes for gain scheduling (adaptive control).builds soft sensors and other advanced process control (APC) schemes inside DCS / PLC.

- has got many PID tuning criteria: integrated absolute error (AIE), integrated square error (ISE), integrated time absolute error (ITAE), reduced overshoot (RO), Ziegler Nichols, Cohen Coon, Internal Model Control (IMC) and Lambda.

- works in offline (Excel) or online (OPC) mode.

Inquire About PITOPS

Talk With The Expert

Contact Email

Info@LeKaControl.com

Call Us

+385 95 8210 600

Office

Meštrovićev trg 8

10 020 Zagreb, Croatia