SUPERTUNE

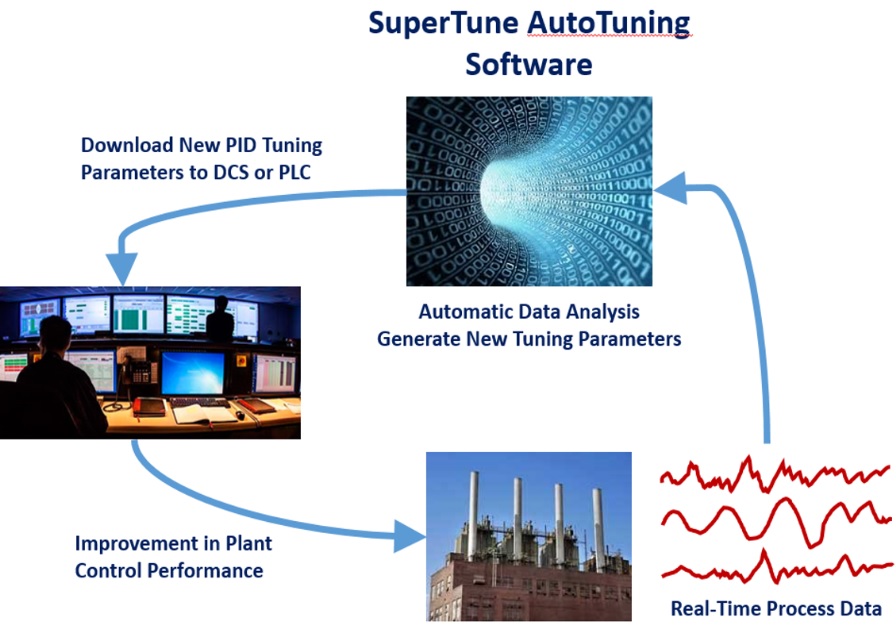

PiControl Solutions software SUPERTUNE is PID control loop auto-tuning product that works reliably for fast and slow processes outperforming any other existing technology. It can easily tackle with control instability and/or sluggishness which can start anytime due to changes in one of many processes and/or equipment characteristics.

SUPERTUNE

SUPERTUNE: Fully Automated Auto-Tuning Software

Many experienced engineers have recently retired. High number of new and inexperienced chemical, process control and similar engineers and DCS / PLC technicians are entering many new plants worldwide. Modern plants are increasingly efficient and also more complex. Due to global competition, tighter government regulations, pollutions laws and the need to operate more efficiently, there are more PID control loops now in plants than before. The newer and more efficient plants lead to more complex PID loop process dynamics, more interactions and more nonlinearities increasing the challenge for PID tuning and creating more chances for PID loop to become oscillatory or unstable. PID control loop oscillations can be a control engineer’s, a chemical plant operator’s or a manager’s worst task to manage. Oscillations could severely impact the ability to run the plant efficiently and could lead to process upsets and even shutdowns causing big monetary losses.

In manufacturing processes, the dynamic models, or process characteristics can change for various known and unknown reasons. These unpredictable changes pose challenges for auto-tuning of PID control loops. If an auto-tuner misses a rare or abnormal situation and is unable to process it correctly, the PID control loop could become unstable or too sluggish and in either cases cause operating problems leading to process upsets, shutdowns or even undesirable or hazardous operating conditions. Moreover, many of the existing PID auto-tuning products need too many intrusive steps on the control valve or final control element in manual mode, or on the setpoint in auto mode. No PID auto-tuning algorithm is capable of reliable PID tuning for all processes ranging from super-fast dynamics to super-slow dynamics, as typically seen in chemical industry. Therefore, chemical and control engineers, and DCS / PLC technicians have long and often been afraid of using commercial and given PID control loop auto-tuning software in chemical plants because of the chance of unpredictable or potentially undesirable or erroneous tuning calculations.

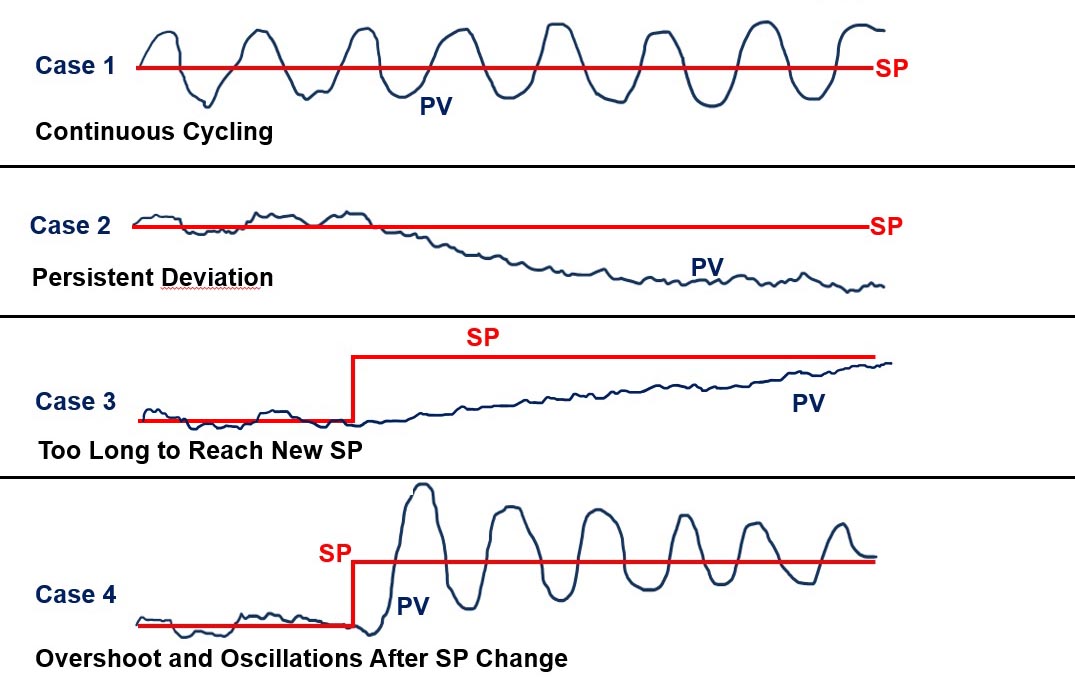

PiControl Solutions software SUPERTUNE is PID control loop auto-tuning product that works reliably for fast and slow processes outperforming any other existing technology. It can easily tackle with control instability and/or sluggishness which can start anytime due to changes in one of many processes and/or equipment characteristics. SUPERTUNE is able to address and fix all four cases of control quality deterioration:

SUPERTUNE can successfully handle multiple simultaneous linear and/or nonlinear processes where the process gain could change by 10 or even 100 times.

SUPERTUNE generates various error codes, messages and criteria calculations useful for understanding what is going on and what control action is produced and why.

SUPERTUNE can successfully and reliably tune both; settling processes (first, second or higher orders), or integrating processes (zero-order). It can also be applied to open-loop unstable processes (exothermic reactions in polymer processes).

SUPERTUNE can be applied to fast processes like turbines and compressors where the settling times are under a second or to temperature and analyzer controllers where settling times are in the 10 to 200-minute range.

SUPERTUNE just reads the PID data, monitors and learns about PID behavior and optimizes the loop tuning parameters without any operator intervention or intrusive step tests.

Inquire About SUPERTUNE

Talk With The Expert

Contact Email

Info@LeKaControl.com

Call Us

+385 95 8210 600

Office

Meštrovićev trg 8

10 020 Zagreb, Croatia